Representation in Eastern Europe:

Phone: + 380 63 171 62 63

Mobile phone: + 380 67 445 11 27

info@epikurgroup.com

Suction press shaft

Drying part of BDM

Bearing structures (frames) for batteries of drying cylinders.

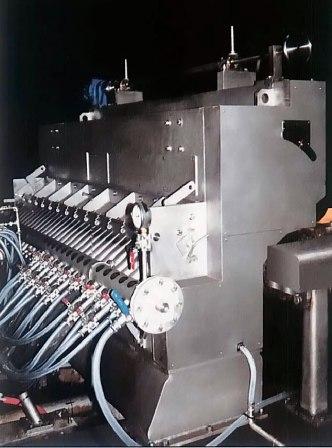

Central mass distributor fed to the pressure box

• Absorption of hydraulic pulsations of mass flow

• Uniform mass flow distribution over the entire width of the machine

• Obtaining a good transverse profile regardless of the width of the machine and the flow

• Adjustment of fiber orientation with a small deviation angle

The central distributor guarantees the absorption of hydraulic pulsation accompanying the main flow of mass from the system of cleaners by quenching the energy of the flow. Ego symmetry allows perfectly even distribution of mass in any operating mode of the equipment. It is connected to the forming block by means of flexible hoses of the same length, which allows feeding the mass without mechanical vibrations.

The distributor provides a uniform and constant profile of the mass, as well as the speed of the flow across the entire width of the machine, which allows you to control the orientation of the fibers.

The distributor - the pulsation damper creates a homogeneous mass distribution during the working cycle, regardless of the quality of the dilution water supplied to the inside of each flexible hose, because the clearance of the lip section is identical over the entire width and the jet speed is constant. The effect on each separate dilution valve makes it possible to independently control parameters such as paper weight and fiber orientation.

The forming block can consist of one or two diffusers (stepped diffuser). The diffuser evenly distributes the mass over the entire width of the pressure box, causes controlled turbulence of the mass to prevent fiber flocculation and provides a uniform flow profile at each stage of the diffuser.

It is recommended to use the stepped diffuser in the process of obtaining a good quality of paper web formation and special mechanical characteristics, which are uniform at all points of the sheet. The stepped diffuser is symmetrical, compact and, thanks to its modular design, can be used in a wide range of productions.

The absence of combined recycling and independent systems for controlling paper weight and fiber orientation allow for quick reconfiguration of the equipment for the production of one or another type of production. That significantly reduces production costs and the cost of production.

Hydraulic pressure box

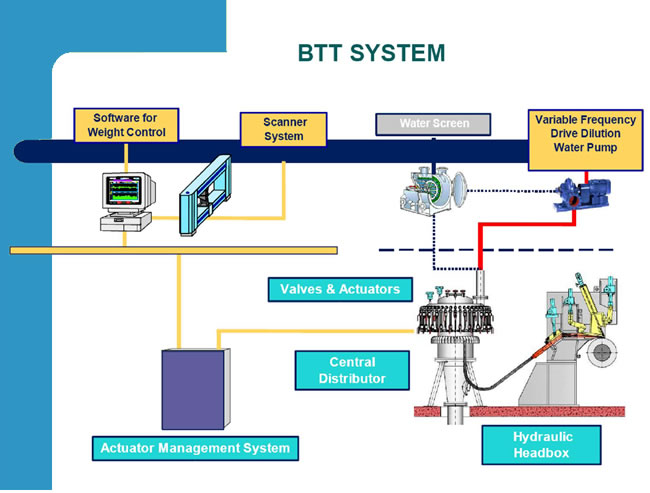

Exclusive system BTT (Basalan Tecnologia Tolosa) is a technological scheme in the design of which is included hydraulic pressure box and three main elements ,

listed below:

• Central distributor-suppressor of pulsations

• Forming block

• Water dilution system

The main task of this system is the damping of pulsations accompanying the main flow of mass from the system of cleaners in a permanent part, as well as the uniform distribution of the mass flow in the direction of the machine and across the entire width of the forming grid. The analysis of the treated water gives indicators of the quality of the formation of the paper layer, which depend on the degree of cleaning of the mass and mainly on the degree of dilution of the mass for feeding into the pressure box.

The key to the BTT system is the Central Distributor. it is structurally included in the pressure box in the forming block, which makes it possible to achieve a uniform distribution of mass flow across the entire width, damping of pulsations and ideal control of the profile of the produced paper, as well as allows obtaining high-quality products and reducing equipment wear.

The determining factor in the high-quality operation of the pressure box is the possibility of optimizing the processes of pouring homogeneously structured paper mass over the entire width and controlling this process. In this case, there is no need to use complex temperature control devices. The use of automatic valves in this system significantly simplifies the operation of the entire BTT system.

The Basalan BTT system significantly increases the productivity of the machine with a simultaneous decrease in operating and raw material costs. Product quality improvement and return on investment starts from the first days of installing this system.

The BTT system is compatible with pressure boxes of other types.